Overview

According to a report by the IMARC Group, titled “Warehousing and Storage Market: Global Industry Trends, Share, Size, Growth, Opportunity and Forecast 2022-2027”, the global warehousing and storage market size reached a value of US$ 451.9 Billion in 2021 and is estimated to reach US$ 605.6 Billion by 2027, exhibiting at a Compound Annual Growth Rate (CAGR) of 4.9% during 2022-2027. The COVID-19 pandemic has increased the need for warehousing and storage facilities to cater to the surging demand for numerous essential goods and healthcare products across the globe. Smart warehousing and logistics are key for the proper preservation of goods and consequently of the public health. Today, real-time tracking of vehicles and goods at the transfer points are very consolidated operations, for both end users and companies. However, the availability of data as well as functionalities such as augmented reality and remote-controlled operations, that can be supported by B5G/6G technologies along the warehousing and logistic supply chain, can enable much more advanced services reducing operational delays and wastes (due to disrupted products which do not reach the consumer market).

This use case intends to demonstrate the feasibility and value of applying distributed intelligence in an overall Smart Warehousing context, for:

- Optimizing warehousing operations with increased performance and improved efficiency;

- Assisting training of new warehouse workers and maintenance of warehouse systems through application of 3D augmented reality, promoting human-robot interaction with 3D video-driven solutions;

- Enhancing the safety of personnel and goods;

- Enabling remote inspection and diagnostics;

- Identification and tracking of goods.

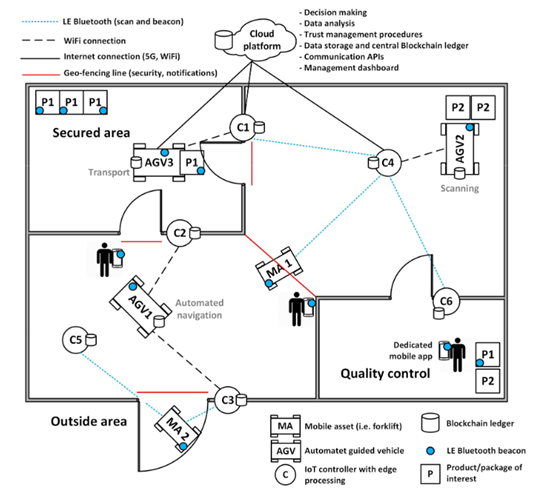

This will be achieved through an integrated state-of-the-art operational system based on AGVs, Internet of Things (IoT) systems and edge computation capabilities supporting deployment of DEDICAT 6G enablers.

Use case stories

The main actors in the smart warehousing scenario are warehouse workers focusing on their daily tasks and warehouse managers/administrators focused on improving overall efficiency, performance, and safety by applying new processes, organizing personnel and resources, and remotely monitoring deployed systems. These main actors will interface with the deployed DEDICAT 6G systems and new technology in different ways. This is why the perspective of 1) a warehouse manager and 2) a typical warehouse worker is described in the two stories.

Story 1: This story puts focus on a warehouse administrator or manager who is responsible for setting up the strategy for improving performance, efficiency and safety of personnel and stored goods. This person also performs monitoring of the deployed resources and configured processes in order to assess performance and derive necessary updates. Finally, a warehouse manager is also responsible for interaction of the smart warehouse systems with the outside world including the wider supply chain. The assumption is that a warehouse manager monitors the operations from a dedicated location/office which might or might not be at the same location as the warehouse itself.

Story 2: This story emphasizes how a typical warehouse worker utilizes deployed technologies to perform daily tasks (goods inventorying, goods shipment, training of a new worker, warehouse maintenance, etc.) more efficiently and safely. Warehouse workers are those who directly interact with the deployed AGVs, goods and other warehousing infrastructure. They are performing all their activities within the perimeter of the warehouse.

Human centric applications

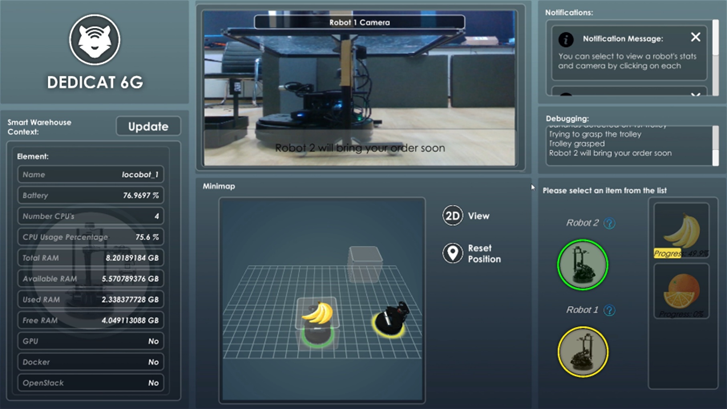

The Smart Warehousing human centric applications essentially aims to address the needs of the Warehouse manager and the Warehouse worker foremostly. In this direction two applications are being developed: a dashboard for the Warehouse manager and a mobile application for the Warehouse worker.

Through the warehouse manager dashboard, the warehouse manager can:

- configure daily tasks for the fleet of AGVs including product quality monitoring parameters, interaction rules with warehouse personnel and product offloading/loading schedule;

- view the overall status of AGVs and processes of the warehouse

- direct personnel or AGVs towards an area of interest or an asset.

- configure safety rules for workers including social distancing and safety zones with configurable geo-fencing zones for different time periods and in line with offloading or loading schedule;

- configure authorization levels for workers with respect to warehouse areas.

The warehouse manager dashboard also allows to view the overall status and processes of the warehouse through dedicated cameras, view notifications e.g., on completed tasks, view precise location of key assets, direct personnel or AGVs towards an area of interest or an asset, view AGV camera feeds, view real time data from the robots such as their status, battery level, availability and other statistical and historical data.

Through the warehouse worker mobile app the worker receives a list of daily tasks as specified by the warehouse manager. A worker can also inspect status reports of AGVs, for example on the result of quality processing. A worker can also direct AGVs towards a product or an area of interest if he/she is authorized to do so. Finally, in the scope of training other workers, one worker can provide another with instructions on how to utilize the AR interface of the mobile App to navigate the warehouse, how to use robots, etc.

The workers training Augmented Reality application will combine real world objects with digital information. For example, a specific model of a robot has on its arm a unique Quick Response (QR) code. The user will be able to target the QR-code with the camera of his mobile device (smartphone/tablet/AR glasses) and have access to the robot’s statistics in real time, download the user’s manual, interact with the 3D model or even watch video and animations explaining how the robotic arm works.